Why Push/Pull Clamps Are Ideal for Space-Constrained Welding Fixtures

Share

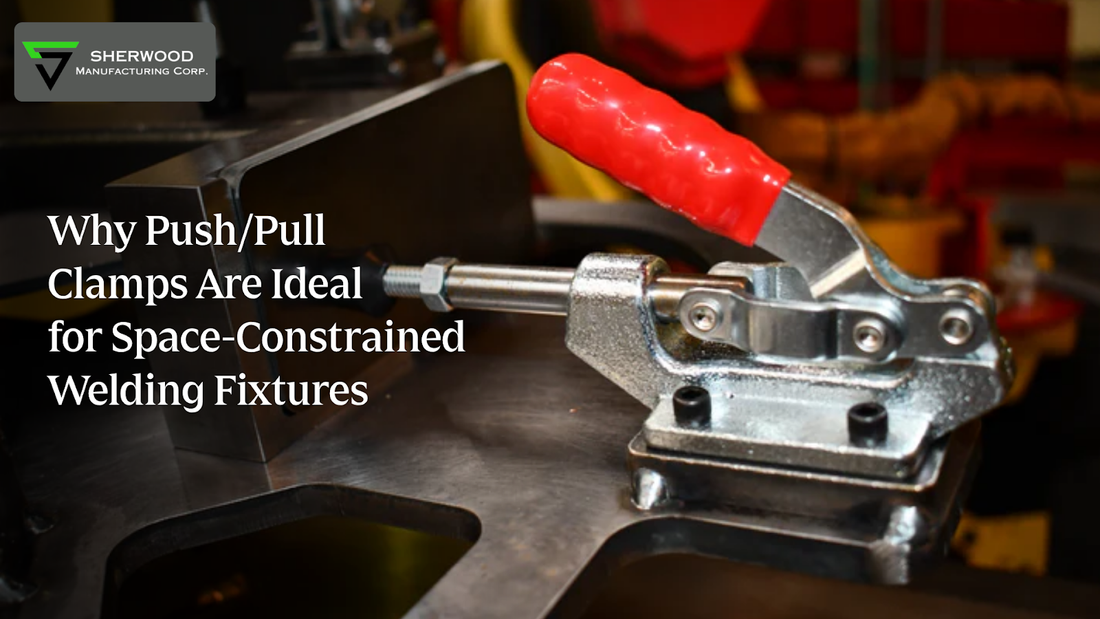

In today’s precision welding environments, fixture space is at a premium. With multi-axis automation, limited bench real estate, and increasingly complex part geometries, every tool in the setup must be compact, precise, and multi-functional. This is exactly where push/pull toggle clamps outperform more traditional hold-down solutions.

When space is constrained and flexibility is required, push/pull clamps deliver controlled linear motion with minimal footprint, allowing for both direct force application and smooth part release in tight setups. More than a workaround, they’re a strategic solution for modern weld fixture design.

How Push/Pull Clamps Fit into Tight Spaces

Unlike traditional toggle clamps that rely on lever arms swinging over the workpiece, push/pull clamps use a Rubber spindle that moves linearly, in or out along its axis. This design drastically reduces the clamp’s profile, enabling placement within confined areas where space is at a premium.

This linear motion also improves force delivery precision. Because the clamp pushes or pulls in a straight line, the clamping force targets the workpiece directly, avoiding the bending or shifting forces sometimes experienced with levered clamps. In fixtures where parts must be held firmly but access around the weld zone is restricted, this precise force transmission is essential.

Furthermore, the locking mechanism commonly employed in push/pull clamps secures the Rubber spindle firmly in either its extended or retracted position, preventing accidental release while providing operators ease of actuation.

Functional Benefits in Welding Fixture Applications

A typical push/pull clamp designed for woodworking or metalworking might feature a rubber contact spindle to protect delicate surfaces, minimizing damage when clamping finished or coated parts. For environments where exposure to heat and spatter is severe, Steel contact components, such as carriage bolts paired with robust mounting systems, offer enhanced durability without sacrificing force consistency.

The low-profile nature of push/pull clamps allows fixture designers to position multiple clamps closely without interference. This capability is particularly important on welding fixtures with dense tooling arrangements or robotic access requirements. Where vertical or horizontal clamps might physically block a torch or sensor, push/pull clamps fit discreetly, holding parts securely without compromising weld quality or operator safety.

The travel distance of the Rubber spindle , commonly around 1-1/4 inches, accommodates variations in part geometry and fixture tolerances. This range often aligns with dimensional fluctuation encountered in welding, especially when parts heat and expand. As a result, clamps maintain consistent pressure without requiring constant readjustment, contributing to repeatability and process reliability.

Modular Mounting and Clamp Reusability

Increasingly, production facilities adopt modular fixture strategies to maximize throughput and minimize tooling costs. Push/pull clamps complement these strategies effectively, particularly when paired with mounting blocks that are welded or bolted onto fixtures.

This approach allows clamps to be easily removed once a job is complete and reused on subsequent fixtures simply by transferring them to new mounts. Such modularity increases asset utilization across diverse production lines, reducing capital tied up in redundant clamps and accelerating fixture changeovers.

Additionally, Sherwood mounting blocks constructed from steel or aluminum provide the rigidity necessary for precise clamping while resisting deformation from repeated use and welding heat, enhancing clamp lifespan and maintaining alignment accuracy.

Practical Industrial Examples

In a metal fabrication shop handling complex exhaust system weldments, engineers have used clamps with oil- and stain-resistant red grips for better operator comfort over repeated clamp cycles. The combination of a rubber spindle protecting finish-sensitive parts and a solid locking mechanism ensures both part integrity and line efficiency.

Workshops with frequent fixture changes leverage modular clamp and Sherwoods mounting block assemblies, enabling rapid redeployment of clamps like push/pull toggle clamps across multiple jobs. This helps maintain lean tooling inventories and reduce fixture downtime, which is critical in fast-turn production environments.

Heavy industrial welding scenarios demand clamps capable of enduring elevated temperatures and heavy cycle counts. In these cases, clamps featuring carriage bolts and jam nuts provide added fastening security, ensuring stable clamping despite high heat shop conditions.

Key Selection Factors for Push/Pull Clamps in Welding Fixtures

Professionals considering push/pull clamps should assess:

• Holding Force Requirements: An adequate holding capacity, commonly around 600 pounds, ensures part stability under welding and handling stresses.

• Plunger Travel Range: Sufficient travel accommodates part variability and thermal effects, minimizing the need for additional adjustment.

• Mounting Flexibility: Sherwoods mounting blocks offer options for fixture adaptability and clamp reuse, aligning with lean manufacturing principles.

• Contact Materials: The choice between rubber and steel spindles depends on part sensitivity and exposure to heat or abrasive elements.

• Grip Durability and Safety: Clamps with resistant handles improve operator experience and extend service intervals in production environments.

Maximizing Workflow Efficiency with Push/Pull Clamps

Integrating push/pull clamps thoughtfully within welding fixtures delivers several operational improvements:

• Accelerated Setup and Tear-down: Locks that hold firmly in multiple positions eliminate lengthy adjustments or cautious repositioning.

• Enhanced Part Consistency: Stable, direct clamping force improves weld quality and dimensional adherence.

• Optimized Space Utilization: Slim profiles enable more clamps per fixture surface area, adding more contact points without obstruction.

• Improved Safety and Ergonomics: Handles designed for resistance to heat and oils ensure safe, comfortable operator interaction.

Application in Advanced Manufacturing Environments

Consider a production line welding automotive subframes. Each fixture must tightly secure odd-shaped brackets and tubes, often with minimal clearance. Engineers routinely specify push/pull clamps like the Sherwood GH-36003-R toggle clamp, which provides a low-profile plunger action and locks in both directions. Its 1-1/4" travel is more than sufficient for handling material thickness variations essential when building to various OEM specifications on the same line.

In another scenario, modular fixtures are a mainstay for job shops handling frequent changeovers. The addition of steel mounting blocks (e.g., GH-36003-RBS toggle system) allows clamps to be rapidly moved between fixtures as required, sidestepping costly investment in dozens of one-use clamping devices. Teams become nimbler, switching from one product run to another without rebuilding entire fixtures.

Heavy welded assemblies prone to heat, spatter, and residue benefit further from robust options like the GH-36003-C pull toggle clamp, equipped with a carriage bolt for enhanced strength and durability. Features such as oil- and stain-resistant grips reduce operator fatigue and fleet maintenance demands.

Frequently Asked Questions

Q: Why choose push/pull toggle clamps over traditional lever clamps in welding fixtures?

A: Their linear plunger design allows installation in confined spaces where lever arms would interfere with tooling or weld heads. The direct axial force also enhances clamping precision.

Q: Can push/pull clamps be reused across fixtures?

A: Clamps paired with modular mounting blocks support quick removal and redeployment, enabling reusability and flexible fixture management.

Q: How do these clamps perform in high-heat welding environments?

A: Models with carriage bolts and secure fastening mechanisms withstand thermal cycling and welding spatter, maintaining clamping force without degradation.

Q: What maintenance do push/pull clamps require?

A: Minimal maintenance includes cleaning contact surfaces, lubricating moving parts, and inspecting for wear, procedures that sustain clamp reliability over extended production cycles.

Q: What are typical holding forces and travel distances?

A: Holding forces near 600 lbs and plunger travel of about 1-1/4 inches are common, balancing strength with adaptability to part and fixture variation.

Conclusion

In the specialized context of space-constrained welding fixtures, push/pull toggle clamps offer a compelling combination of compact design and strong, repeatable force. Their linear actuation mechanics allow for precise, secure part holding without increasing fixture complexity or footprint. When paired with Sherwood's mounting solutions, these clamps provide production teams the flexibility to optimize fixture layouts, reduce downtime, and react swiftly to evolving job requirements.

For production engineers, fixture designers, and shop floor supervisors focused on efficiency and quality, push/pull clamps represent a mature, practical solution that integrates seamlessly into modern welding workflows, helping to maintain throughput, improve product consistency, and safely manage constrained workspace challenges. Visit Sherwood Manufacturing.