What Is a Solid Arm Toggle Clamp?

Share

Introduction

If you’ve worked on welding projects, woodworking, or machining setups, you know how important it is to keep workpieces firmly in place. That’s where toggle clamps come in. But not all toggle clamps are the same, some are built for flexibility, others for strength.

One of the newest clamping solutions available today is the solid arm toggle clamp attachment. Unlike open-arm clamps with interchangeable spindles, solid arm clamps offer unmatched durability and holding power, making them the preferred choice for high-demand welding and metalworking environments.

So, what exactly is a solid arm toggle clamp, how does it differ from an open arm version, and how do you pick the right attachment? Let’s explore everything you need to know so you can choose the right tool for your job.

What Is a Solid Arm Toggle Clamp?

A solid arm toggle clamp is a clamping tool with a fixed, non-adjustable arm, designed to deliver stability and consistent holding force. Unlike open arm clamps that allow multiple spindle or knob attachments, a solid arm clamp comes with a solid arm and simple bolt retainer attachments, offering:

• Higher rigidity for heavy-duty applications.

• Safety and reliability during repetitive tasks.

• Simpler design with fewer adjustments needed.

They are commonly used in welding toggle clamps, machining fixtures, and manufacturing lines where strength and repeatability matter more than flexibility.

Solid Arm vs. Open Arm Toggle Clamp: The Key Differences

When choosing between clamp types, it helps to compare solid arm vs. open arm toggle clamps:

• Solid Arm Toggle Clamp: Strong, fixed design for consistent force. Ideal for heavy-duty holding and repetitive applications.

• Open Arm Toggle Clamp: Adjustable design with interchangeable parts (like rubber spindles or knobs). Perfect for woodworking and metalworking.

In short, choose solid arms for power & durability and open arms for flexibility.

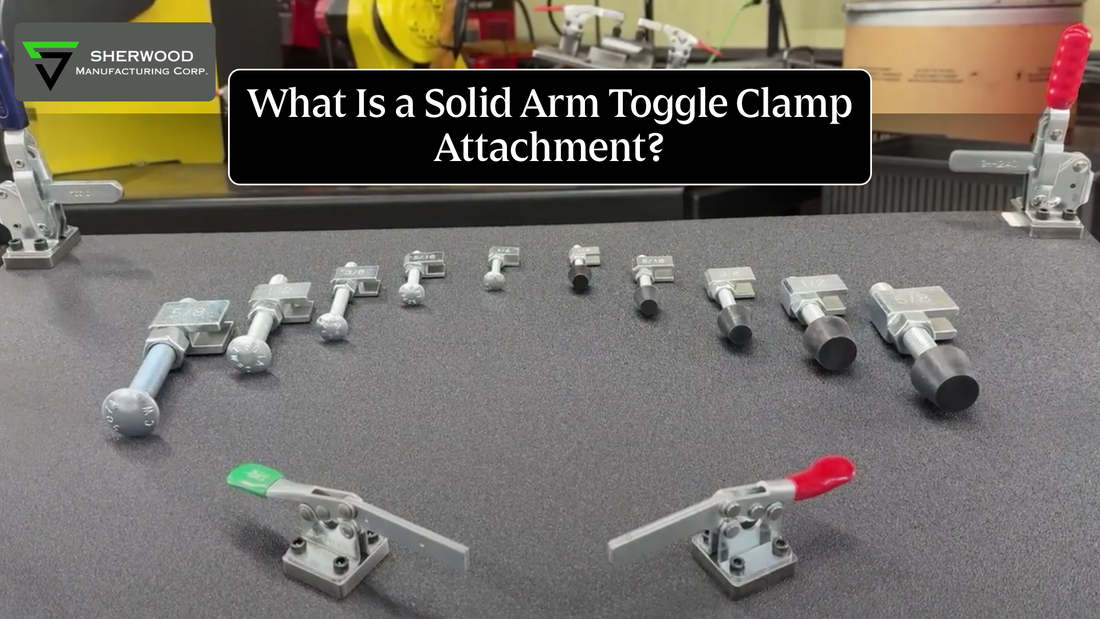

Types of Solid Arm Toggle Clamp Attachments Available

While solid arms don’t have as many variations as open arms, they rely on bolt retainer attachments to provide effective clamping. Sherwood Manufacturing offers a safer more durable option in various sizes based on different sized clamps.

What is an External Threaded Bolt Retainer?

Sherwood’s External Threaded Bolt Retainer is designed for solid arm clamps, allowing operators to cut off the spindle top for extra safety. This prevents accidental contact with sharp or protruding parts during clamping.

The Sherwood External Threaded Bolt Retainers range from ¼” - ⅝” sizes and offers two different variations: rubber spindle for moderate heat and carriage bolt for high heat applications. Each of these options provides safe, low-profile operation ideal for professionals seeking both strength and workplace safety.

Explore Sherwood’s Solid Arm Toggle Clamp Attachments Collection for bolt retainers and other accessories designed for maximum safety and performance.

When Should You Use Solid Arm Toggle Clamp Attachments?

Solid arm clamps excel in applications where maximum pressure, minimal adjustment, and safety are top priorities. Here’s when they should be your go-to:

• Welding Fixtures & Jigs: Their rigid strength ensures materials stay aligned even under stress.

• Machining Operations: Solid arms prevent vibration-induced slippage, protecting both tools and parts.

• High-Volume Manufacturing: Their simple, sturdy design requires less adjustment, saving time in repetitive tasks.

If you’re looking for reliability over versatility, then solid arm clamps with external bolt retainers are your best option.

Advantages and Limitations of Solid Arm Toggle Clamps

Advantages

• Provide stability and strength for rugged tasks.

• Lower risk of attachment slippage compared to adjustable designs.

• Require less frequent adjustments ideal for production environments.

• Safer designs when paired with products like bolt retainers.

Limitations

• Less flexible than open arm clamps.

• Not ideal for projects requiring frequent adjustment or softer rubber contact points.

How to Maintain Solid Arm Toggle Clamp Attachments

Maintenance ensures long-lasting performance:

• Clean regularly after welding sessions to remove debris.

• Apply light lubrication to moving parts and pivots.

• Inspect bolt retainers for wear or damage.

• Trim spindle tops (using Sherwood’s attachments) to prevent accidents and maintain safety.

• Replace if clamps show signs of cracks, rust, or weakened locking strength.

FAQs

Q1: What is a solid arm toggle clamp?

It’s a fixed-arm clamping tool with bolt retainers, built for heavy-duty applications in welding, machining, and woodworking setups.

Q2: How is a solid arm toggle clamp different from an open arm clamp?

Solid arms are stronger and provide consistent holding power, while open arms allow interchangeable attachments for flexible use.

Q3: What are solid arm toggle clamp attachments?

They allow operators to cut off the spindle top for extra safety. This prevents accidental contact with sharp or protruding parts during clamping. Sherwood’s External threaded bolt retainers come in ⅝”, ½”, ⅜”, 5/16”, and ¼”.

Conclusion

A solid arm toggle clamp attachment is built for two things: strength and consistency. It’s the ideal choice for professionals in welding who require dependable clamping without constant adjustments.

While these clamps may not offer the same versatility as open-arm designs, their combination of durability, and efficiency makes them a cornerstone in many workshops. Paired with Sherwood Manufacturing’s external bolt retainers, you gain an added layer of protection and long-term usability.

By understanding the differences, benefits, and practical uses of solid arm attachments, you’ll be able to make informed decisions that improve both workflow safety and project accuracy.