The Benefits of Auto-Adjusting Toggle Clamps in Modern Manufacturing

Share

Introduction

On a busy shop floor, every second counts. Imagine a team working on a batch of metal assemblies yet, they keep losing time because each workpiece requires manual readjustment of the clamps. The constant tightening, loosening, and repositioning not only slows down production but also frustrates workers and increases the risk of errors.

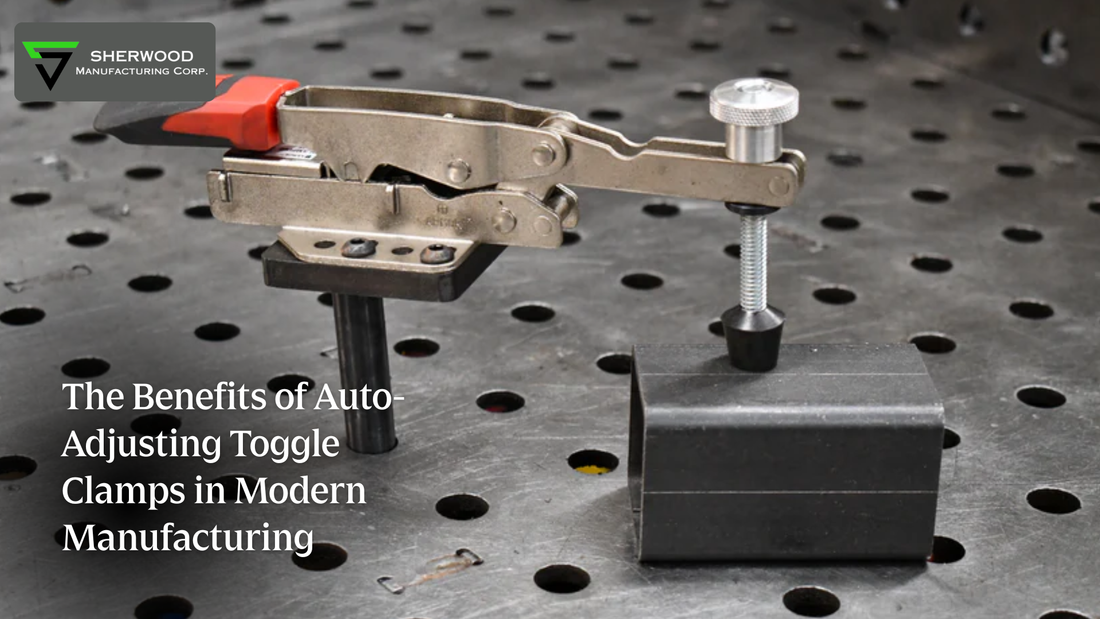

This is where auto-adjusting toggle clamps make a real difference. Unlike traditional clamps that need frequent tweaking, auto-adjusting versions adapt instantly to different material thicknesses without sacrificing pressure. The result? Faster setups, consistent clamping, and a smoother workflow across welding, woodworking, and manufacturing lines.

Modern manufacturers are rapidly adopting these solutions to reduce downtime, improve safety, and support lean practices. If you’re looking for reliability and efficiency in your workshop, exploring the auto-adjusting clamps collection from Sherwood Manufacturing is a smart place to start.

What Makes Auto-Adjusting Toggle Clamps Different?

An auto-adjusting toggle clamp is a specialized clamping tool designed to secure workpieces of varying thicknesses without requiring manual readjustment. Unlike standard clamps, where you need to tighten or loosen a threaded rod for each new part, auto-adjusting clamps automatically regulate clamping force to match the material’s size. This innovation saves both time and effort while ensuring consistent pressure.

The key difference between a traditional adjustable toggle clamp and an auto-adjusting version lies in flexibility. A standard adjustable toggle clamp needs constant fine-tuning ideal when you’re working with uniform parts but time-consuming for mixed production runs. In contrast, auto-adjusting toggle clamps adapt instantly, eliminating setup delays and reducing operator fatigue.

These advantages explain why auto-adjusting clamps are rapidly gaining traction across industries. Manufacturers appreciate their ability to boost productivity, minimize human error, and maintain a strong, reliable hold even in high-pressure environments. Whether it’s in metal fabrication, woodworking, or even specialized assembly environments like automotive and aerospace applications, auto-adjusting clamps are quickly becoming a standard tool in modern manufacturing.

Key Benefits of Auto-Adjusting Toggle Clamps

Reduced Setup Time and Downtime

One of the biggest challenges in fast-paced manufacturing is the constant need to adjust clamps for every new workpiece. Traditional clamps require threading, tightening, and retesting before production can even begin. With auto-adjusting toggle clamps, that frustration disappears. These clamps automatically adjust to varying material thicknesses, eliminating the need for frequent manual adjustments.

This not only saves valuable minutes per task but also reduces downtime across entire production runs. On welding and assembly lines, where efficiency is everything, the ability to clamp once and move forward quickly translates into faster output and smoother workflow.

Consistent Clamping Pressure Across Workpieces

Consistency is key in manufacturing. A slight variation in clamping pressure can lead to misalignment, poor welds, or even unsafe setups. Auto-adjusting clamps solve this by applying uniform pressure across workpieces of varying sizes whether thin sheet metal or thicker assemblies.

For instance, the STC-IHH25-618-1-00-RR is designed to deliver reliable, repeatable pressure without constant adjustments. By maintaining this consistency, manufacturers can ensure higher-quality results while reducing the risk of errors during production.

Built for Harsh Environments

Manufacturing floors aren’t always the cleanest or easiest environments. From sparks and heat in welding shops to dust and oil in woodworking spaces, clamps are exposed to constant wear and tear. That’s why many professionals prefer stainless steel adjustable toggle clamps, which are resistant to rust and corrosion.

A strong example is the STC-HH50-618-1-00-RK, engineered with durability in mind. Its heavy-duty build and corrosion-resistant design make it a reliable option even under extreme conditions, ensuring long service life and dependable clamping strength.

Improved Ergonomics and Operator Safety

Workers on the shop floor often handle clamps hundreds of times a day. Traditional adjustable toggle clamps can strain wrists and hands due to constant threading and manual adjustments. Sherwood’s auto-adjusting clamps eliminate tool-based setup, offering quick, tool-free adjustments made possible by their patented attachments.

This means less fatigue, fewer repetitive strain injuries, and safer overall operations. By reducing the physical effort required, auto-adjusting toggle clamps create a more ergonomic environment, which directly boosts employee efficiency and morale.

Supporting Lean Manufacturing Practices

Lean manufacturing focuses on cutting waste and boosting efficiency, and auto-adjusting toggle clamps align perfectly with this approach. Every moment spent tightening or adjusting a clamp for different material sizes is wasted time that could go toward real production. By removing these unnecessary steps, auto-adjusting clamps directly support lean principles.

One of the biggest benefits is the reduction of setup waste. Traditional clamps require workers to constantly tweak and retest, which slows down operations and disrupts workflow. Auto-adjusting clamps, on the other hand, adapt instantly, keeping production lines moving smoothly. This makes them ideal for companies striving to achieve lean efficiency in welding, woodworking, and metal fabrication.

These clamps also play a critical role in Just-in-Time (JIT) production systems. In JIT environments, where inventory and processes are tightly controlled, downtime caused by inefficient tools can disrupt the entire system. Auto-adjusting clamps ensure that every workpiece is secured quickly and consistently, minimizing delays and keeping production in sync with demand.

By aligning with lean principles, reducing waste, and supporting JIT systems, auto-adjusting toggle clamps do more than just hold materials in place; they actively improve overall workflow and productivity.

Where Auto-Adjusting Clamps Are Used Most

Automotive Assembly – Auto-adjusting clamps speed up workflows by securing parts of varying sizes without constant resetting, making them valuable for fast-paced car production lines.

Woodworking & Furniture – Craftsmen benefit from the ability to switch between materials of different thicknesses quickly, improving efficiency in custom and mass furniture production.

Metal Fabrication – From welding to cutting, Sherwood’s auto-adjusting clamps provide strong, reliable holding for metal workpieces, saving time in setups and changeovers. Though versatile, they’re primarily designed for metalworking applications.

Global Adoption Trends – Their use is rapidly growing in the U.S., Canada, and Europe, driven by the shift toward leaner, automated, and more flexible manufacturing systems.

Maintenance Tips for Longer Clamp Life

To maximize the lifespan of auto adjusting toggle clamps, proper care is essential:

-

Cleaning and Lubrication – Regularly remove dust, metal shavings, or adhesives that can build up on moving parts. Light lubrication keeps the mechanism smooth and prevents wear.

-

Checking Alignment – Ensure clamps stay aligned to maintain proper holding force. Misalignment can reduce clamping accuracy and increase strain on components.

-

Preventing Corrosion – Wipe down clamps after use, especially in humid or dusty environments. Applying protective coatings or rust inhibitors helps extend life.

- Why Stainless Steel Clamps Excel – Stainless steel models naturally resist rust and wear, making them ideal for long-term use in demanding manufacturing environments.

Frequently Asked Questions

Q1: Are auto-adjusting clamps better than standard toggle clamps?

Yes. Auto versions save time, maintain consistent pressure, and require fewer manual adjustments, making them more efficient in most manufacturing settings.

Q2: Can one clamp handle multiple material thicknesses?

Absolutely. That’s the key advantage of an auto adjusting toggle clamp: it adapts automatically to different workpiece sizes.

Q3: Do stainless steel adjustable toggle clamps prevent rust completely?

While stainless steel offers superior corrosion resistance, proper maintenance (like cleaning and lubrication) ensures the best long-term performance.

Q4: Are auto adjusting toggle clamps worth the investment?

Yes. The time saved from reduced downtime and improved operator efficiency typically outweighs the upfront cost.

Q5: What industries benefit the most from these clamps?

Industries like automotive, aerospace, woodworking, and metal fabrication see the greatest productivity gains from using auto adjusting clamps.

Conclusion: Why Manufacturers Are Switching

Auto-adjusting toggle clamps are revolutionizing modern manufacturing. By cutting setup time, providing consistent pressure, and excelling in harsh environments, they outperform traditional adjustable toggle clamps in every aspect. Their ergonomic design also enhances worker safety and comfort, making them a smart investment for forward-thinking manufacturers.

As manufacturing continues to evolve toward efficiency and precision, auto adjusting clamps will remain at the forefront of innovation.

If you’re looking to boost productivity and streamline operations, explore Sherwood’s auto adjusting toggle clamps collection crafted to deliver reliability, speed, and performance for the future of manufacturing.